SERIES 024 – SINGLE ACTING

SERIES 026 – DOUBLE ACTING

Custom designed, oil activated, high clamp force, pre-tensioning devices.

- Standard black oxide finish for 120°C max. (250°F)

- Alloy tool steel body parts

- Stainless steel, electroless nickel or chromium plating for optional corrosion resistance

- Clean, efficient handpump operated or with hydraulic power unit

SERIES 023

Hydraulic pre-tensioning with mechanical locking for long term clamping at precise tie rod elongation.

One of the principal advantages of the Amtec Block Nut is its availability for rapid release for adjustments or changes on equipment to which it is attached. A sudden product jam, a broken roll or knife, can be handled within minutes; pressurize, unscrew lock ring, release pressure, make required equipment repairs or changes, re-pressurize, tighten lock ring, release pressure, resume operation.

Amtec Block Nuts are custom engineered to meet specific pre-tensioning conditions for rolling mill frames, pinion stands, crop shear housings, plate and strip levelers, injection molding machines, and mechanical or hydraulic presses, to name just a few applications. Using a power unit or handpump, simply pump into the pressure chamber to cause separation between the body and the thrust collar. Since the body of the nut is threaded onto the tie rod, the tie rod stretches in response to the force created by input pressure. When a desired stretch is achieved, screw down the exterior, knurled lock ring tight against the thrust collar, blocking any future shrinkage of the tie rod for the entire period of operation, whether the operating period is for months or years.

- Standard black oxide finish for 120°C max. (250°F)

- Alloy tool steel body parts

- Stainless steel, electroless nickel or chromium plating for optional corrosion resistance

- Clean, efficient handpump operated or with hydraulic power unit

MODELS 901-903

MODELS 921-923

MODELS 931-933

MODELS 941-943

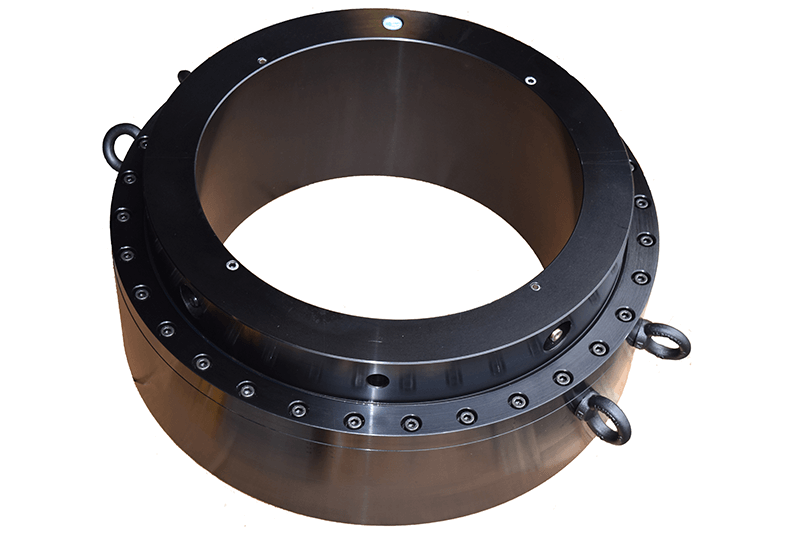

Hydraulic clamp rings use extreme internal pressure to clamp directly to plain arbors. Using our F-Nipples and handpump to bring the pressure chamber to over 10,000 PSI (700 bar) results in tons of friction force to keep knives, discs or spacers fixed firmly in place. No thread required!

Amtec Hydraclamp Clamp Rings are precision engineered and manufactured to the tightest tolerances. When selecting and using clamp rings, it is imperative you understand your arbor(s)must also be precision engineered using the highest quality, hardened steel to ensure the clamp ring has a perfect surface to grasp. Any burs, dents or deformation will prevent either complete installation or effective clamping.

Because clamp rings are pressure welded prior to precision grinding, some deformation of the ID may be possible after pressure cycles, even in spite of annealing and normalization. Some cases my require Amtec Hydraclamp to regrind the ID to remove any elliptical deformation.

Please contact your local distributor or Amtec Hydraclamp directly for the available configurations and sizes of Clamp Rings.